Since its inception, apina, has stood out for the realization of original projects, which in many cases have become technological challenges. Some of them have been copied or imitated by others, but until today, our technology remains unique, since the name of apina is still synonymous of great know-how in the market. Since the incursion in ammonia absorption techniques in which apina was a pioneer, and developing automated industrial refrigeration systems, apina has incurred in the world of U.L.T (Ultra Low Temperature) with the apiUltraLow Technology, taking advantage of all the knowledge obtained during the 80’s by his technical team. This technology has become one of the most exciting challenges, as it is up to now an unknown technological battlefront.

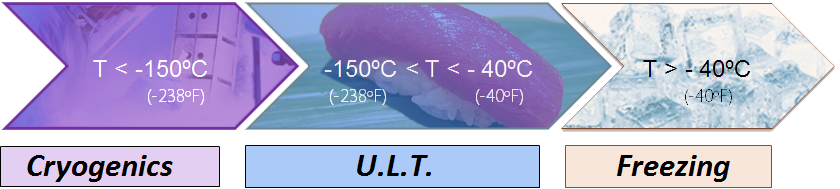

But what is U.L.T in fact?

We define the U.L.T as the range between the standard freezing and cryogenic, covering the temperatures from -40ºC to -150ºC.

While conventional freezing and cryogenics have a market and its materials adapted to each technology, the U.L.T is a field still unexplored in the technical aspect. The applications are multiple, and goes from the food sector (freezing of fish at -60ºC for sashimi) to the research sector (maintenance of organisms in laboratories), although always with the requirement of a very high precision and efficiency.

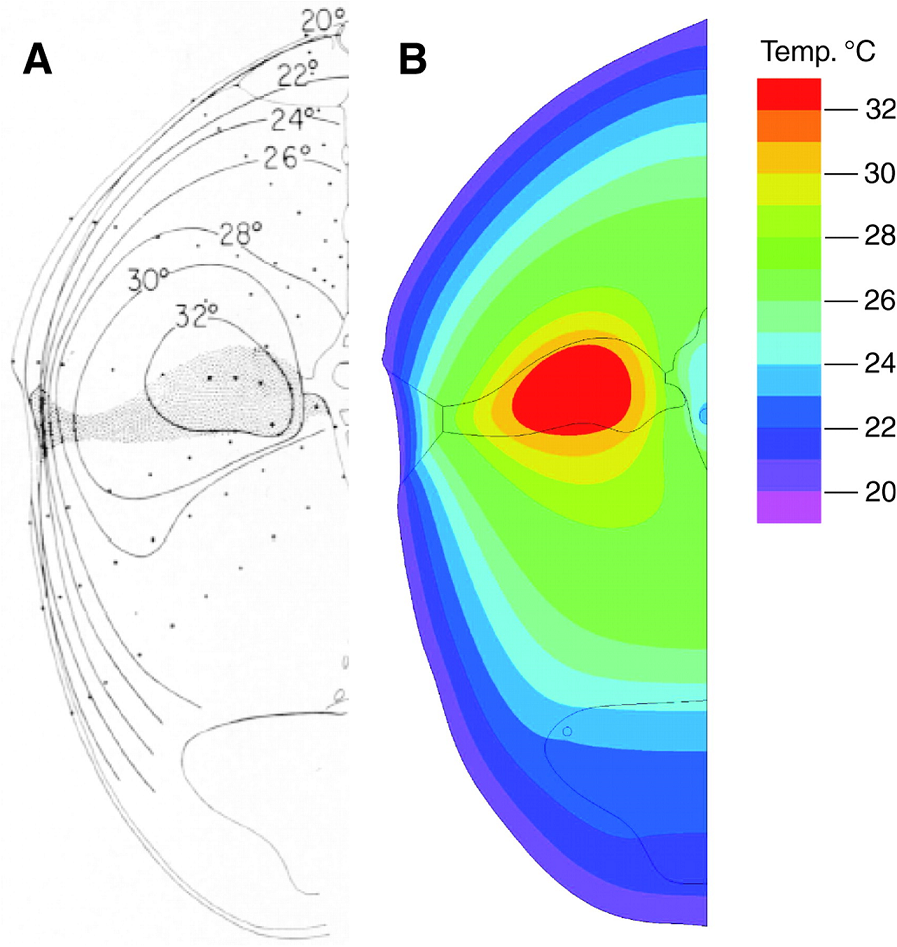

In the food sector, and even more so in the industrial fishing sector, the freezing process is extremely important. The quality of the products depends on the freezing procedure, and the temperatures reached during this process at each step, since this will define the freezing speed of the product (in centimeters of frozen product per hour), always looking for the highest speed to avoid denaturation of proteins and oxidation of the fats that compose it.

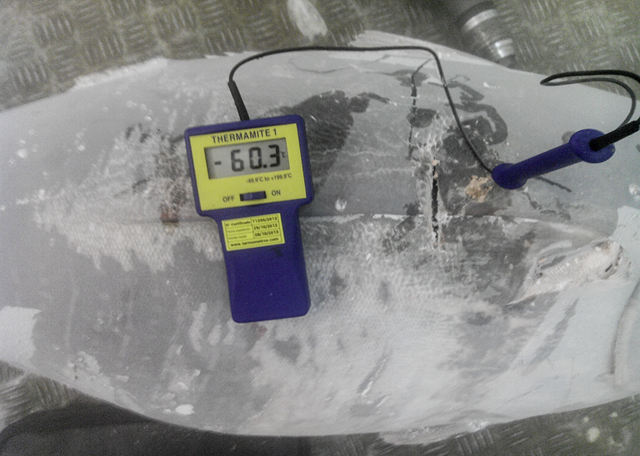

Since the 80s, apina has concentrated its efforts on investigating and optimizing the fish freezing and conservation process, trying to reach optimum temperatures. During these studies it was concluded that a freezing temperature below -45ºC satisfactorily preserves the product, being optimal at -60ºC, overcrossing the thermal inertia of 1cm/h.

ULT 1st Gen

The first realizations of apina in this field were the application of the ULT to the freezing of the swordfish. In these first-generation facilities, the temperature of -65ºC was reached during the freezing process in tunnels, and the frozen product was stored at -45ºC, with a capacity of almost 500 tons. These installations were made from 1988 on the longliners SIETE DE JULIO, RADOCHE I, MAYI SEIS, IBSA IV and IBSA V.

The technology used in these vessels required the use of doble stage systems based on R22 at the high pressure stage, condensing a second stage of R13-B1 at the low pressure stage. The low pressure stage evaporated directly in the tunnels and warehouses, by direct expansion. With these systems, the temperatures in the evaporator could reach -70 ° C at its minimum value.

ULT 2nd Gen

With the prohibition of refrigerants harmful to the ozone layer, both R22 and R13-B1 were eradicated in cold installations. Apina had to make an evaluation of the combinations of refrigerants capable of providing U.L.T, preserving the same characteristics as the original system. At the same time, the needs of the market changed, and with the entry into the European market of the sashimi and other meals based on raw fish, the application of the U.L.T was oriented towards the tuna market.

Strong in its experience in conventional freezer plants in tuna vessels, and with a first draft of ULT with the Elai Alai, in mid-2006 apina made its first U.L.T plant for the tuna sector on the ALAKRANA vessel.

The vessel consists of two fast-freezing tunnels at -60ºC / -70ºC, depending on the required regime, and two holds at -50ºC / -55ºC . The facilities of this ship were the first realization of this type.

The update of the technology used, imposed that this installation be piloted in manual mode, with a minimum of automatisms. For this reason, apina’s R&D department began to develop a third generation of ULT.

ULT 3rd Gen

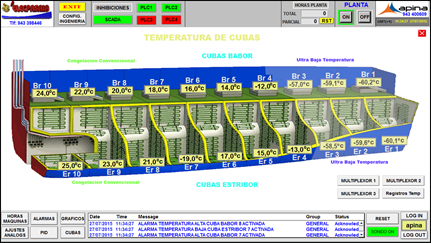

In 2012, market needs evolved again, and after the success of the ULT in the ALAKRANA vessel, the task of equipping 3 state-of-the-art vessels with ULT plants, the IZARO, was entrusted to apina, with the JAI ALAI and the EUSKADI ALAI.

The vessels are composed of 2 fast-freezing tunnels at -70ºC, and 6 conservation tanks at -60ºC .

In this case, and after the studies carried out during the second generation stage, it was decided to change part of the design, in order to optimize the plant. During the tests carried out, the quality of the freezing installation has been confirmed, checking the temperature ratios reached.

ULT 4th Gen

Throughout the life of the third generation, the improvements have been adapted to the needs of our customers, developing completely independent plants, with a superior performance to those of previous generations. The different tests carried out have allowed the improvement of the installed systems. These improvements have reached the development of a design of the fast freezing tunnels, which have evolved during the development of the third generation, thus reducing the freezing cycles in the tunnel to 10 hours per 2T cycle, which allows multiply by 2 the freezing capacity of the plant if necessary. These improvements make it possible to ensure a freezing of the product at -60ºC in thorn.

Similarly, exceeding the operating limits of commercial materials involved a study of the components that made up the plant. For that reason, the materials used in U.L.T plants are adapted and developped by apina for a specific use below -70ºC and with the capacity to operate with a temperature gradient greater than 100ºC.

With the evolution of new technologies, and the requirements of refrigerant gases, apina is facing today the study of a fourth generation, adapting to the needs and demands of its time, and taking profit of the biggest ULT know-how in the fishing market.