Nowadays, climate change has been in the focus. We all know about the consequences of the most of the synthetic refrigerants and their real impact in the environment. A lot of efforts are done all over the world about this problem, trying to find replacement gases. One of the best ways to reduce the environmental impact may be to adapt the cooling plant to a natural refrigerant, but this option is not always possible. That’s where the Refrigeration Control Systems become essential.

In any way there is something to care about, which may have a real incidence: the consumption versus the produced cooling power. The COP/EER is also a key issue to be sure that you reduce your footprint. The better it is, the more efficiency you will gain. Screw compressors showed us that it was possible to optimize the consumption with a capacity regulation, which allows the machine to be fitted to the need at any evaporation temperature. Anyway, this was not the final solution, as a compressor is always at his top cooling production capacity when his capacity is at 100%.

When the speed and frequency converters became common during the last years, this problem was almost solved, and it was possible to use the best performances of the compressors maintaining it at 100% of capacity, while the real cooling capacity was controlled. Then, the control system would be focused into the motor speed, allowing different possibilities.

But what about the regulation? The regulation through an optimized control system is probably the most important thing to take care about during the refrigeration process, and this will also be the image of your consumption, cost, and indirectly your carbon footprint. Taking care about the right speed, and also about the best combination of right capacity with right speed is crucial to have the most optimized and the most efficient refrigeration control system. Added to that, it helps to increase the product life with less maintenance.

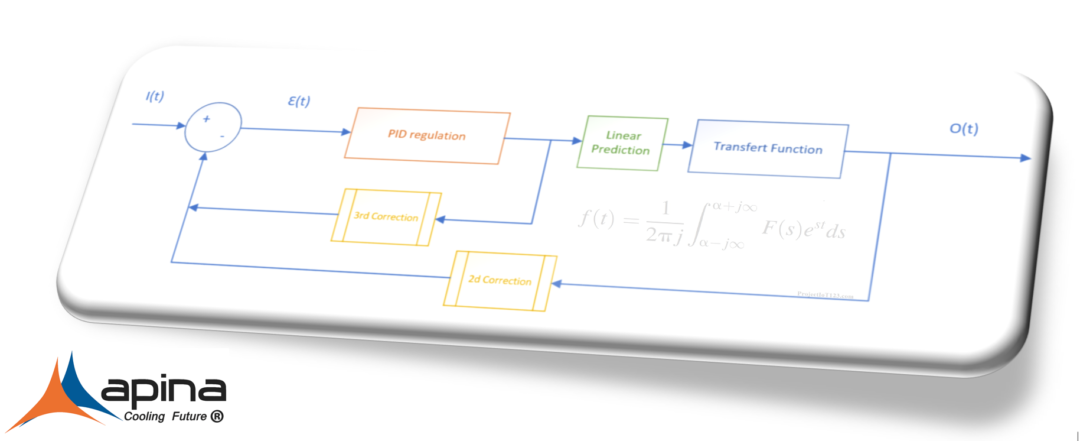

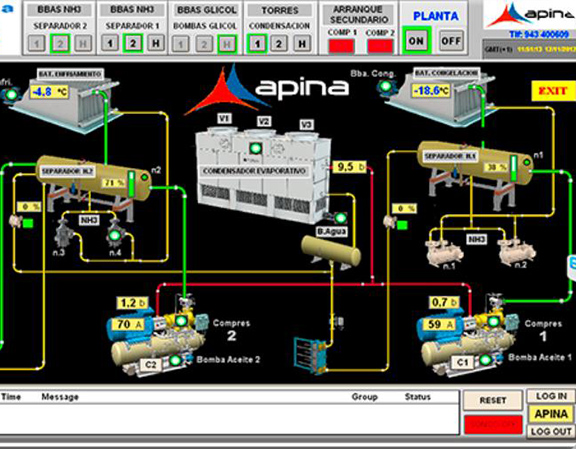

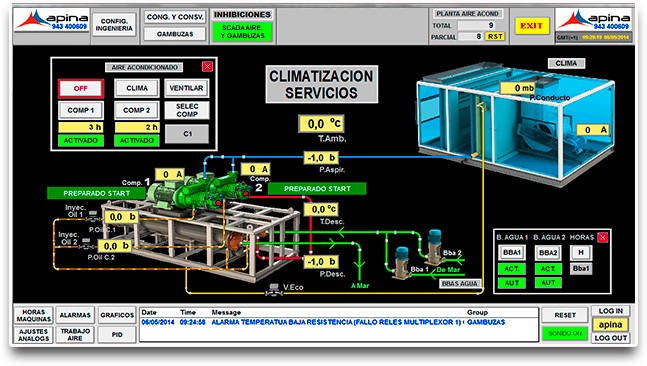

That’s the reason why in Apina, we take care about the regulation of our refrigeration plants, making them unique. Our control systems are created, programmed and tested by our engineers, in our facilities, with our own algorithms, which allows us to integrate years of knowledge and experience in our regulation processes. Adapted and custom made regulation loops, from special PID loops, to linear prediction algorithms, specially developed by our engineers, allows us to optimize the production, reduce consumption, and contribute to a better world.